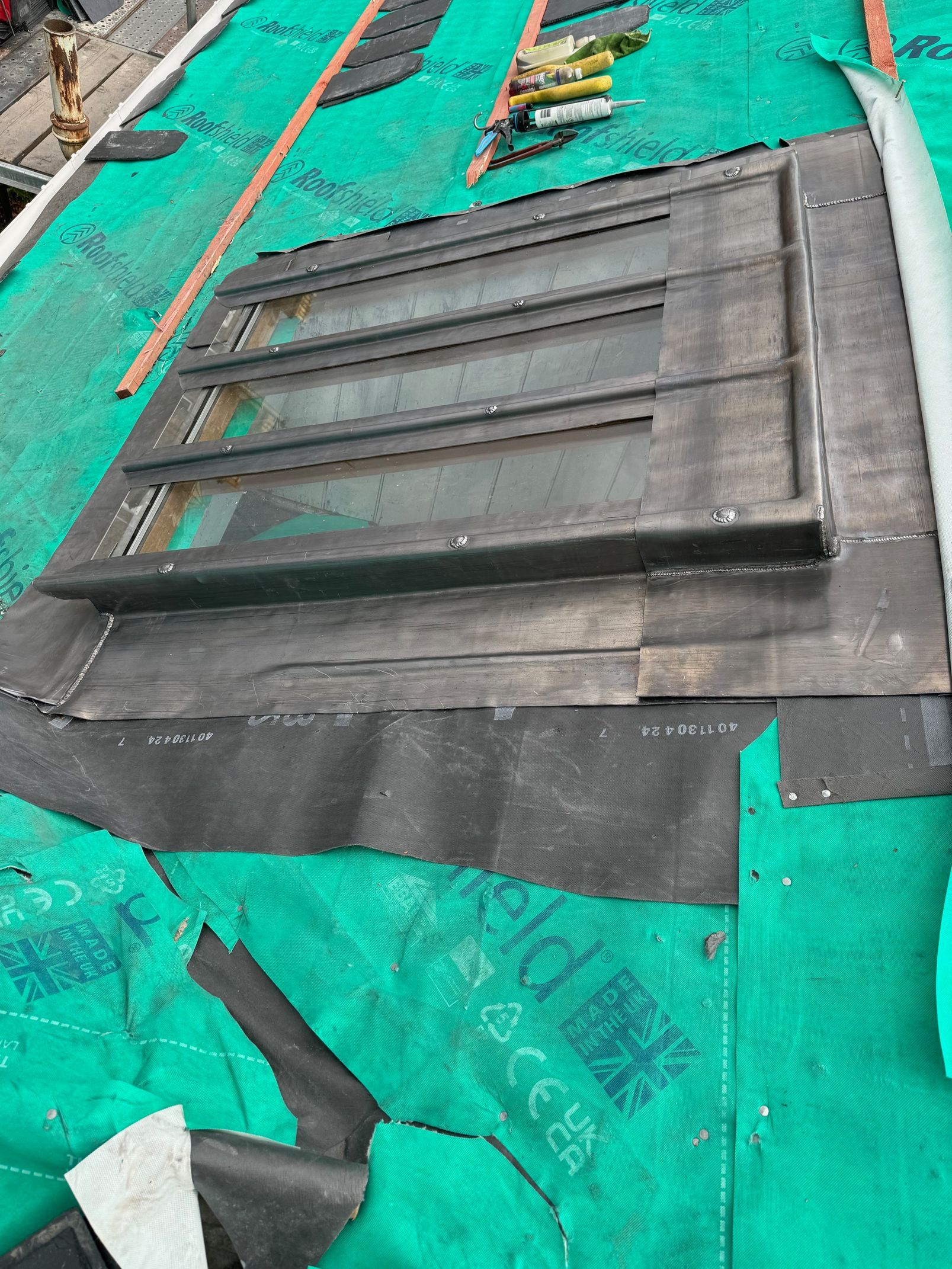

Flashing is used to seal and protects joints in buildings from water penetration. The joints created by the intersection of the roof itself, and roof mounted structures, such as chimneys, windows or skylights are among the most vulnerable areas of roofing systems. Most building materials expand and contract to some degree in response to changes in humidity and temperature, creating the potential for moisture to creep in. The greater the number of roof structures or intersections, the greater the potential for serious leaks. We use flashing at these intersections to keep rainwater from leaking into the building. It makes joints at these junctions watertight, while at the same time allowing the natural expansion and contraction of materials to continue. How Roof Flashing Works We install flashing at intersecting roofs and walls. It typically consists of angled strips of metal that overlap in such a way as to direct water away from areas on the roof in which it might otherwise gather. Flashing is usually composed of two parts: the base flashing and cap flashing (also known as counter flashing). Base Flashing is the portion of the installation attached to the roof itself. It is “L-shaped” with one leg extended underneath the roofing material at least six inches, preferably more, and the other leg extending up the abutting vertical surface. Cap Flashing is attached to the wall or structure with which the roof intersects and overlaps with the base flashing by at least six inches, so that water cannot penetrate the joint. A lot of roof damage and deterioration is caused by flashing failing to do its job properly. It’s worth regularly inspecting (especially after sever weather) to ensure that it remains watertight and efficient at its job. Replacing roof flashing on older roofs in a timely manner can save considerable cost further down the line, and for new roofs, it should be one of the primary considerations in the planning stages. See our roof flashing repair page for more information.